Aluminum Drawing

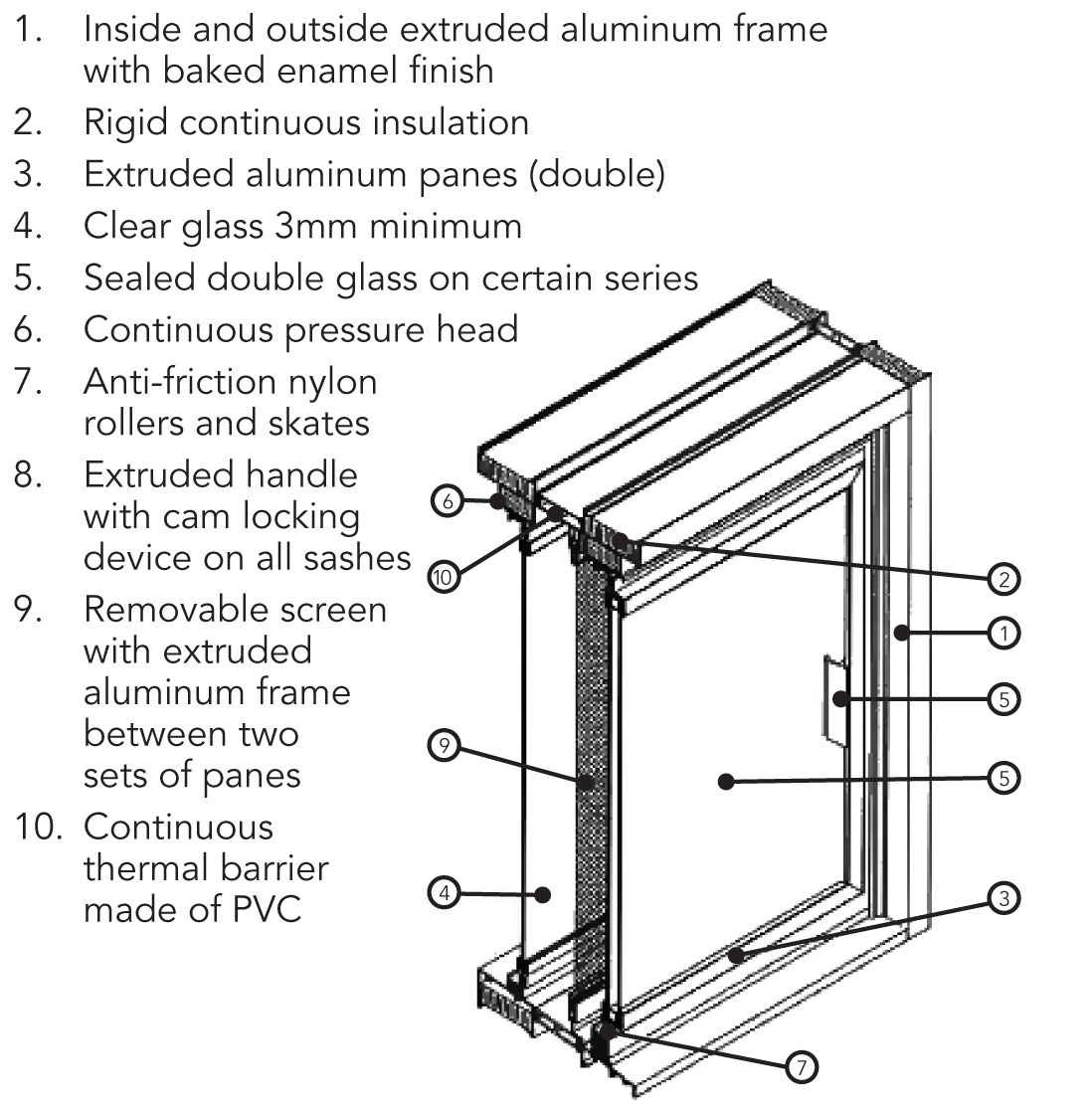

Aluminum Drawing - Web two of the most commonly used processes for shaping aluminum include the extrusion process and the drawing process. This wire is supplied to the drawing site in coils and is drawn in various steps, using a sequence of different machines, down to the final diameter, which can be as small as 0.1 mm, or bigger than 4 mm for cable production. This process stretches the aluminum into a shape that mirrors the die, which can range from simple forms like cups to complex components. The following article provides an overview of the aluminum deep drawing process. Web select the filter below to find applicable cad or pdf drawings. Web prepare cad drawings for your aluminum projects. 48k views 4 years ago. Web deep drawing—also known as deep draw or deep drawn stamping—is a forming process used to create metal parts and products with heights equal to or greater than their widths. To calculate the blank size needed for drawing the round cup, calculate the surface area into a flat. It discusses why you should use aluminum for deep drawing operations and how the material is formed during deep drawing operations. Web aluminium is one of the most popular wire drawing lubricants as it has various advantages as mentioned under: Web two of the most commonly used processes for shaping aluminum include the extrusion process and the drawing process. For those manufacturing operations that revolve around the deep drawing of steel, the sheer mention of aluminum brings out a. The metal. Cad software is an indispensable tool for industrial designers to explore their design ideas. Web american aluminum company is a leading manufacturer of deep drawn parts, including cylinders, enclosures and irregular shapes. 48k views 4 years ago. To calculate the blank size needed for drawing the round cup, calculate the surface area into a flat. For those manufacturing operations that. Drawing metal & metal forming. Web by art hedrick. Web select the filter below to find applicable cad or pdf drawings. See aluminium drawing stock video clips. There are three major categories of finishes: Aluminum unfortunately often gets a bad rap. Web american aluminum company is a leading manufacturer of deep drawn parts, including cylinders, enclosures and irregular shapes. Web neat oils for aluminum rod drawing can be in the viscosity range of kinematic viscosity (kv40c) 100 to 500 centistokes by the method astm d445, the actual viscosity can be dependent on the lubricant. Your aluminum profile is manufactured on the most modern extrusion lines. Aluminum shapes, rod, bar, tubes, and wire may be produced directly as extrusions or by subsequent processing of continuous cast stock. It offers improved heat removal. There are three major categories of finishes: Aluminium wire drawing offers a cleaner wire, machine, and system. Cad is the process of creating sketches and drawings using a computer system. Web the basic material in aluminum wire drawing is a cast wire with a diameter of 9.5 or 12 mm. When comparing the two, there are a few key differences. Extrusion of aluminum drawing profiles. It discusses why you should use aluminum for deep drawing operations and. Lower viscosity oils are typically used for intermediate and fine wire sizes where the drawing oil is of a. How does quantity affect pricing? Extrusion of aluminum drawing profiles. By custom aluminum extrusion manufacturer | august 26th, 2020 | aluminium extrusion. Cad software is an indispensable tool for industrial designers to explore their design ideas. To calculate the blank size needed for drawing the round cup, calculate the surface area into a flat. Web american aluminum company is a leading manufacturer of deep drawn parts, including cylinders, enclosures and irregular shapes. How does quantity affect pricing? Read on to learn about the aluminum extrusion and drawing processes, as well as tips for how to choose. At asd we are committed to service, time, quality and responsibility in all our work. Drawing metal & metal forming. Your aluminum profile is manufactured on the most modern extrusion lines. Metal & alloy selection for metal drawing and hydroforming. There are three major categories of finishes: Aluminum unfortunately often gets a bad rap. The metal thickness, the metal type, and the blank size. Metal & alloy selection for metal drawing and hydroforming. Web the resulting parts and products are both strong and lightweight. Increases the productivity of the wire drawing machine. Deep drawing is a valued fabrication method as it produces a seamless product. Web select the filter below to find applicable cad or pdf drawings. Several stages are used in the process and appropriate lubrication is required. Web 4,485 aluminium drawing images, stock photos, 3d objects, & vectors | shutterstock. Web the aluminum association publication 45, “designation system for aluminum finishes,” is an organized system for calling out various finishes, appearances and in some cases coating thickness ranges for a wide variety of anodic finishes for aluminum. Web the resulting parts and products are both strong and lightweight. Aluminium wire drawing offers a cleaner wire, machine, and system. Deep draw depth & process. 48k views 4 years ago. It discusses why you should use aluminum for deep drawing operations and how the material is formed during deep drawing operations. Web the basic material in aluminum wire drawing is a cast wire with a diameter of 9.5 or 12 mm. Increases the productivity of the wire drawing machine. An ideal product designed for an aluminum stretch draw. Deep drawing involves pulling a sheet of aluminum, or “blank”, into a die using a mechanical punch. There are three major categories of finishes: Web understanding the deep drawing of aluminum:

Aluminum Dimensional Drawings Learn More About Aluminum Dimensional

Chemical Symbol For Aluminium

Aluminium Al (Element 13) of Periodic Table Elements FlashCards

Aluminium Draw YouTube

Aluminium Drawings at Explore collection of

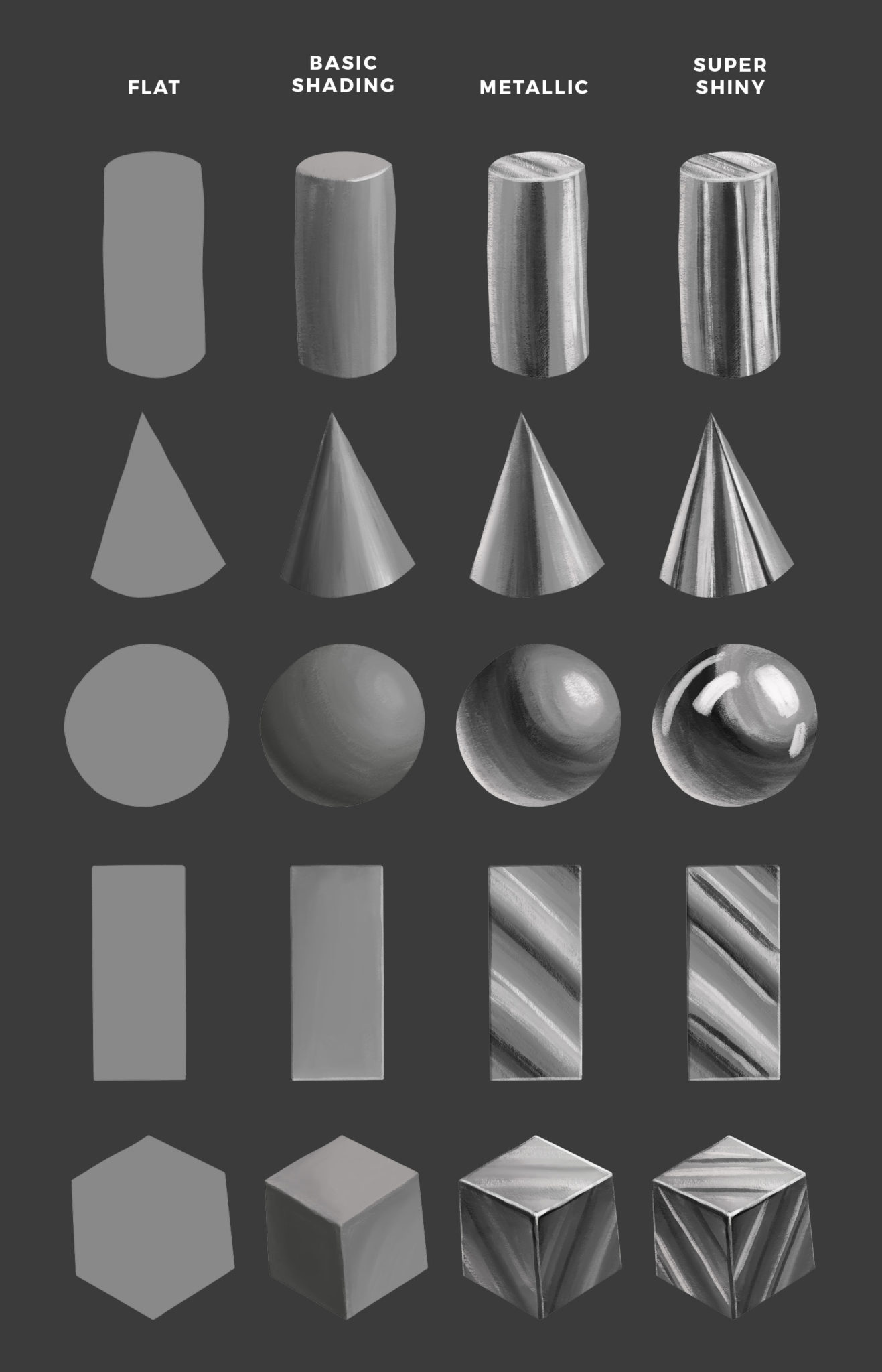

How to Draw Metallic Surfaces the Easy Way • Bardot Brush

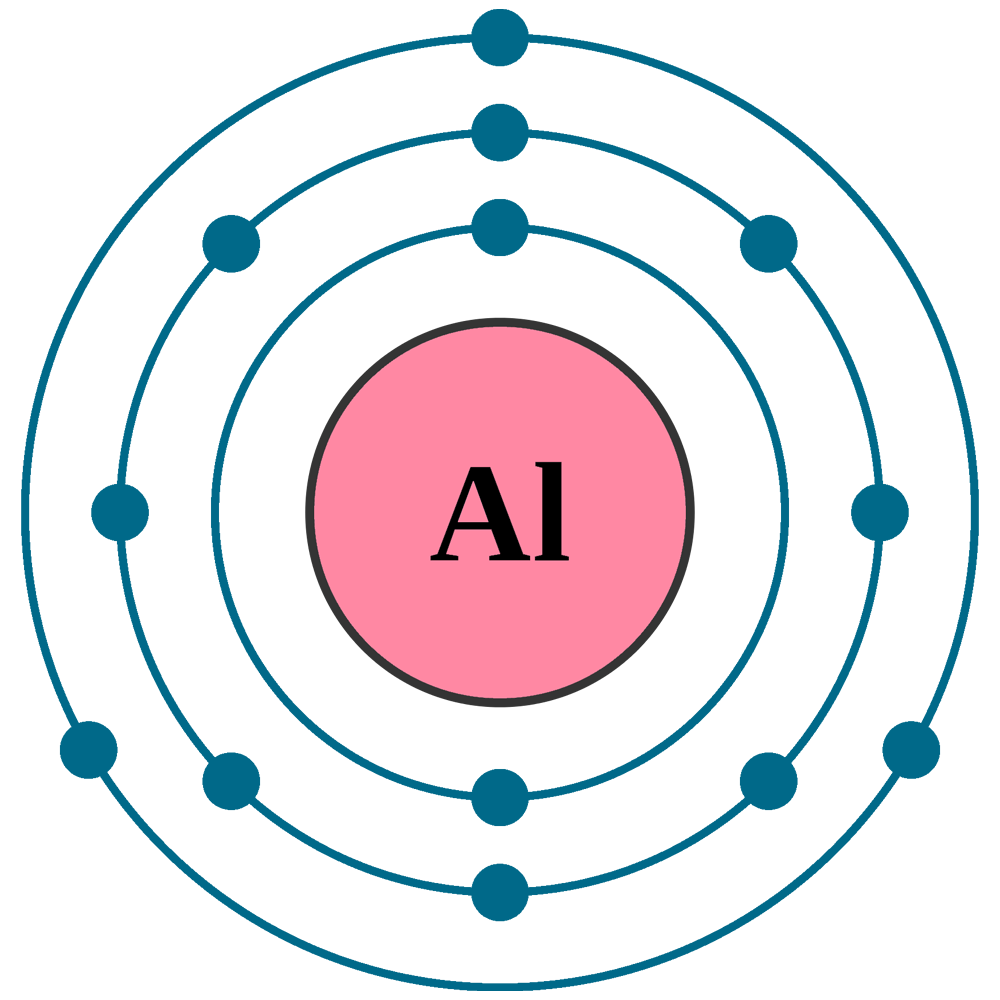

18+ Aluminum Atome

Deep Drawn Aluminum Stampings from Charles Richter

How to draw a metal ingot aluminium aluminum YouTube

Aluminum ClipArt ETC

Web By Art Hedrick.

Web Neat Oils For Aluminum Rod Drawing Can Be In The Viscosity Range Of Kinematic Viscosity (Kv40C) 100 To 500 Centistokes By The Method Astm D445, The Actual Viscosity Can Be Dependent On The Lubricant Supplier And Formulation.

Search By Image Or Video.

Web American Aluminum Company Is A Leading Manufacturer Of Deep Drawn Parts, Including Cylinders, Enclosures And Irregular Shapes.

Related Post: